GEEK LEVEL – 1

Client: Sophisticated Rebel

Assignment: Design for mass manufacturing a stainless steel lipstick applicator that is refillable. Also design a simple clear plastic cartridge that can be filled with raw lipstick and be used to refill the applicator.

Challenges: Almost too many to list.

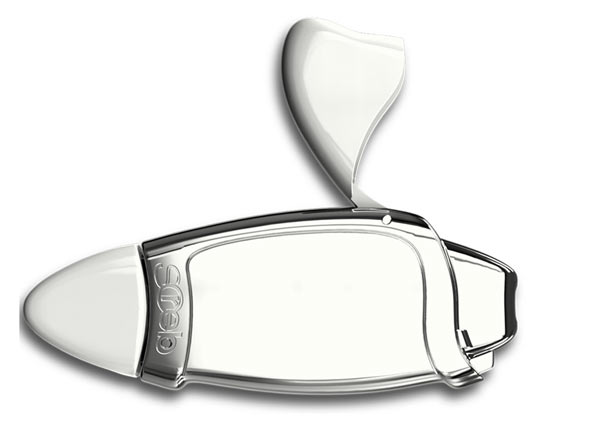

The Forever Lipstick Applicator “Blade” was the second version of this product that I designed, prototyped and had manufactured. Version 1 was made from plastic and although proved the flat lipstick concept could work, had too many problems to fix and eventually had to be scrapped in favor of a higher end model with a one piece body.

The Forever Blade is made up of an assembly of 14 individual parts. Each of those had their own design problems, most notably the one piece body. This one piece body design was something that was absolutely necessary to eliminate the problem of the plastic version, namely the two halves splitting apart and letting lipstick ooze everywhere.

The challenge was that every “expert” told me the design was impossible to injection mold in one piece. It had too many curves, inside cavities, thin body sides, etc. To make matters worse I insisted it be made from stainless steel since a major feature of a flat applicator was being refillable. The metal would make it durable and stainless steel would eliminate any future lawsuits arising out of a growing social perception that metal leeches into our food – in this case lipstick. Most of the concern is completely overblown but I was not taking any chances with zinc or nickle and decided on medical grade stainless steel – the metal most devices used, or implanted in the human body, are made of.

DESIGNING: The flowing shapes of the body, cap and knob were modeled first in Lightwave, my special effects software, then ported to Rhino and finished up in Geo Magic as a solid model. Getting the cap to click shut and stay shut without any mechanism inside was a tough nut to crack. I actually discovered it by accident while working with a 3D printed prototype of the body. Adding a small wedge and making sure the plastic cap was thin enough to flex finally nailed the design.

The knob was another major hurdle, getting it to click STOP and stay stopped. On the plastic version I simply added nubs to the inside axle but there was a lot of play – like the steering in my old Econoline Van, and that would not be good enough for this higher end model. I ended up using two spring loaded ball bearings as stop clicks. I had to run a dozen 3D printed prototypes to get that to work right.

3D printing is a great process but to get accurate parts for proper size fits means giving up strength. What you learn is you have about 5 times to try out a working part before the contact surfaces start to wear away and the fit becomes loose and unusable. If you go with a stronger resin, the part is not as dimensionally accurate. It’s a trade off for sure and you really never know exactly how it’s going to work until you make REAL parts.

The development from design to manufacture on this product was considerable: over a year. It helped that I had a great team made up of Portuguese, British and Chinese technical personnel who helped make sure the product was made to specs and assembled with care.

TID BIT — To mold complex shapes in Stainless Steel is done with MIM – or metal injection molding. It’s a very cool process and it’s used for a lot of very high precision small parts. They start by making the mold 20% BIGGER – meaning your part is 20% larger than you designed it. Then they inject the mold with a mixture of steel powder and plastic resin. Once it hardens, they put that larger version part in an oven and SINTER it for 18 hours. The process melts the plastic and the part actually SHRINKS 20%, fusing the metal powder in the process and when it’s done, the part is back to its original size. How the hell they get it to be accurate to .001 inches is pretty heady to even think about.

THE CARTRIDGE

This is the matching REFILL Cartridge I designed to mate perfectly with the Forever Blade’s nozzle. it holds 4.5 grams of lip color, which is more than a traditional wax based lipstick.