GEEK LEVEL – 8

The MEAN GREEN CNC grew out of my need (and desire) to have a computer controlled metal cutter. I had learned machining as a hobby on a small manual Mill and doing any kind of decent work was very stressful and time consuming. Milling metal, even aluminum, takes a very stable machine because every flex puts its imprint right on the surface you’re cutting. Making smooth curves on a machine like that is next to impossible, even with a rotary table. I design from emotion and emotion is not straight lines – I wanted curves!

There are hundreds of DIY CNC projects online to gain research from. One of the best sites is of course CNCZONE which I would recommend to anyone trying to do this yourself. Like always I just started surfing and dropping pictures and email threads into a folder to build up a data base.

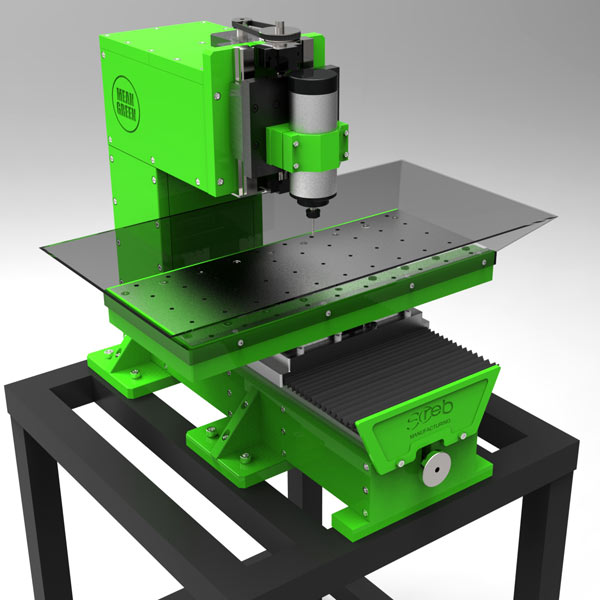

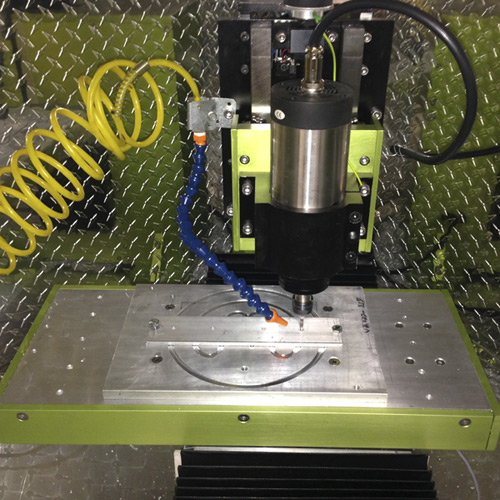

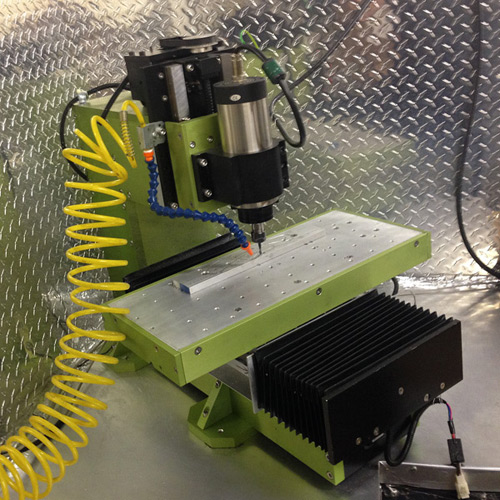

I discovered that most of the DIY machines were of the ‘router’ type. They have a large bed with the cutting spindle moving on an X axis (side to side) gantry. Many claimed they could cut aluminum with ease but at what speed and what about steel? I also noticed that many were made from the popular 20/80 aluminum extrusions. Those are standard pieces like an erector set for adults and although they are very versatile in what you can create, I had a specific machine in my head. Since I didn’t need to make large pieces, I went for more of a solid design made from a box of 3/4″ thick cast aluminum plates. I wanted the cutting spindle to be rock stable and so far, that decision had worked out fantastic. The spindle is a high speed one (24,000 rpm) but for milling steel I can crank it down to the slower speed steel demands and there is still plenty of power to cut.

Specs: X axis Travel: 11.5″ ( I will update it to 16″ soon)

Y axis Travel: 10.2″

Z axis Travel: 3.8″

Spindle is 1.5 KW 220 VAC on a 3 Phase line.

Working with computer controlled motion – robotics as some might call it – was not new to me. I had designed and built my own motion control tracks back in Florida to do special visual effects with. These tracks were huge because they had to move an 80 pound motion picture camera with pin point accuracy. This new CNC would be a lot smaller but it needed to be as rigid and accurate if I was going to be able to make precision parts – sometimes really tiny precision parts.

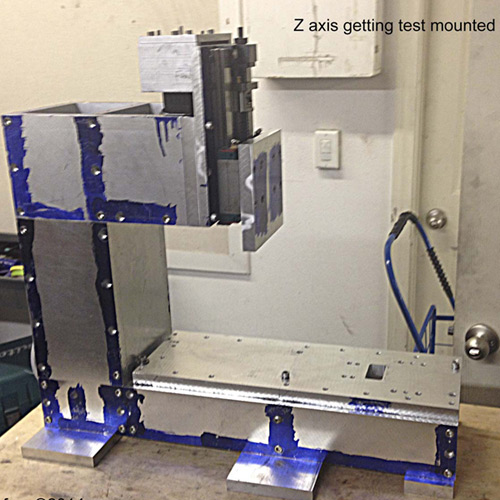

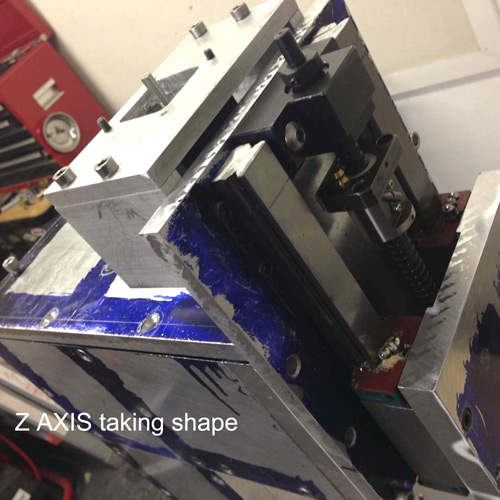

A few pics of the building progress.